How the horizotnal mechanic came About

When It All Started

Returning home to Missouri from working in the oil field. I Found that my brother had three slipped discs in his back. Though he was on painkillers he could barely walk. A man takes great pride in taking care of his family. You can imagine the struggles he was facing mentally and physically.

A few years earlier we put a Cummins motor into his ford pickup. There were things on that truck only he knew how to fix. With his back the way it was he could not do the work that was needed to keep it running properly. At 26 years old I had some challenging health problems arise . From that experience I learned that I was able to do everything I could before. Which meant I just had to do things in a different way. After explaining this to my brother he told me that since he could not find a way, that I had to find it for him.

Determined To Find A Solution

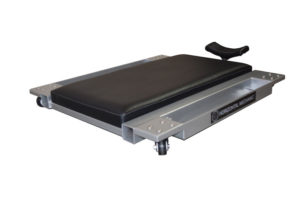

My first thought was a creeper that would get him above the engine, instead of underneath. It had to be adjustable to his low rider 1982 Mustang GT nd his 1 ton 4×4 pickup. It had to be easy to operate, and get onto because of his back. I went into his shop with a welder and a chop saw , and junk steel I found laying around. I made what looks like the bottom of an engine hoist for the frame. With square tubing I made an extendable ladder. I welded an old creeper to the frame, and put casters under it.

My brother was able to lay on it and work on his truck. His teenage sons found it so useful to do general maintenance that we ended up having to change the casters on it.

What We Now Call The Horizontal Mechanic

We used this in the shop for a few years. I added a few things like leg rests along with a head and chin rest. I made it so the creeper detaches to work as a normal creeper. It took up too much space so we had to find away to fold it up. This way there was no danger of it falling over on someone or the equipment in the shop. Now it stands on a footprint 21”x26” and 3 1/2′ tall when folded up and it folds out easily to work on a low rider or a 1 ton 4×4 pickup in seconds.

The finished product is a creeper designed for the professional shop manager who is worried about their customer’s cars as well as their employees safety. In 2017 we spent a month at DWS classics, working on a redesign. The new product brings back memories of an age when tools were made to last.